When it comes to food safety, shelf life, and product quality, one of the most overlooked yet critical factors is Water Activity (aw). Whether you’re dealing with fresh produce, packaged meals, or meat products like pork, controlling water activity is essential for managing microbial growth and ensuring food stays safe and stable over time.

If you work in food production or quality control, you know the constant battle against spoilage and pathogens. For perishable products like pork, this battle is intense. While temperature control is crucial, there’s another, often overlooked, scientific principle that dictates whether microorganisms thrive or die: Water Activity (a<sub>w</sub>).

Understanding and controlling water activity is perhaps the most powerful tool in your arsenal for ensuring product safety, extending shelf-life, and maintaining quality. Let’s dive into what it is and why it’s so critical, especially for pork meat samples.

In this post, we’ll explore what water activity is, how it affects perishable foods, and why it’s especially important in pork meat samples.

What is Water Activity (aw)?

Water activity (aw) measures the amount of free, unbound water in a food product that is available to support microbial growth, chemical reactions, and enzymatic activity.

It’s expressed on a scale from 0.0 to 1.0, where

- 0.0 = completely dry (no available water)

- 1.0 = pure water (all water is available). Note: Water activity is not the same as moisture content. A food can have high moisture content but low water activity if most of the water is bound (e.g., in sugars or salts).

Moisture Content is a quantitative measure. It tells you how much water is in a product—the total percentage of water by weight. It answers the question, “How much?”

The Sponge Analogy: Imagine a soaked sponge and a slightly damp one. Both contain water, but the water in the soaked sponge is free to drip out, use, and interact with. The water in the damp sponge is tightly bound within its structure. The soaked sponge has a high water activity; the damp sponge has a low water activity. Food works the same way.

Water Activity & Microbial Growth

Microorganisms, including bacteria, yeasts, and molds, need available water to grow. The higher the water activity, the more likely microbes are to multiply. Each type of microorganism has a minimum aw value below which it cannot grow.

Minimum aw Requirements for Microbial Growth:

| Microorganism | Minimum aw Required |

|---|---|

| Most bacteria (including pathogens) | ~0.90 |

| Most yeasts | ~0.88 |

| Most molds | ~0.80 |

| Xerophilic molds | ~0.65 |

| No microbial growth | Below 0.60 |

Water Activity in Perishable Foods: Focus on Pork Meat – A Case Study

- Raw Pork

Raw pork typically has a very high water activity — around 0.98 to 0.99. This means that nearly all the water in the meat is available for microbial use.

As a result, raw pork is:

- Highly perishable

- Prone to spoilage

- A potential carrier of pathogenic bacteria such as:

- Salmonella spp.

- Listeria monocytogenes

- Escherichia coli

- Clostridium perfringens

For quality control, knowing these specific thresholds is vital:

- Staphylococcus aureus: A major concern in cured meats. It can grow at a minimum a<sub>w</sub>of ~0.83 under aerobic conditions and can produce a heat-stable toxin. This is why a<sub>w</sub> is a critical control point for many ready-to-eat meat HACCP plans.

- Salmonella: Minimum a<sub>w</sub>for growth is around 0.94. Ensuring a product is safely below this threshold is a key safety step.

- Listeria monocytogenes: A resilient pathogen that can grow at refrigeration temperatures. Its minimum a<sub>w</sub>for growth is around 0.92. For products like deli ham, a combination of hurdles (low temperature, preservatives, and a<sub>w</sub> < 0.92) is essential for control.

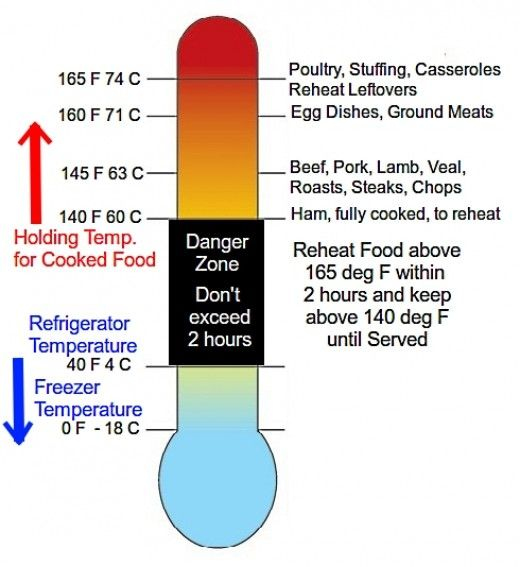

Unless it’s quickly processed, refrigerated, or cooked, raw pork becomes unsafe to eat in a short time due to microbial growth.

- Processed Pork (Cured, Dried, or Fermented)

Processed pork products (such as cured ham, sausages, or jerky) go through techniques like salting, drying, or fermentation, which help reduce water activity.

By lowering the aw, these processes make the environment less favorable for bacterial growth, particularly dangerous pathogens.

Example Water Activity Levels:

- Cured ham: aw ~0.88–0.92

Inhibits many bacteria but may still allow yeast or mold growth. - Dry-cured sausage: aw ~0.85 or lower

Prevents most bacterial growth and even Staphylococcus aureus toxin production.

This is why dry-cured pork products are often shelf-stable, while fresh meat requires refrigeration.

Case Study: Water Activity and Spoilage of Brown Rice Syrup Due to Fungal and Mold Growth

Background: One of our industrial clients, engaged in the manufacturing of clarified and brown rice syrup, recently experienced a product rejection and return shipment from a buyer located in a European country.

Brown rice syrup is a natural sweetener derived from cooked brown rice and enzymatic breakdown of starches into sugars. It is commonly used in health foods, granola bars, and organic food products.

While syrups generally have low water activity (aw) due to their high sugar concentration, brown rice syrup has a slightly higher water activity than refined syrups, making it more susceptible to spoilage under certain storage conditions.

The rejection was due to the following identified issues:

Problem:

A natural food company experienced unexpected spoilage in multiple batches of brown rice syrup stored in bulk containers. Within 2–3 weeks, some containers developed:

- Visible mold colonies on the surface

- Discoloration and slight separation

- Off-odors, described as sour or fermented

The affected product batches had been stored at room temperature (~25°C) in plastic drums with loose-fitting lids.

Investigation:

The company initiated a microbiological and physicochemical investigation, which revealed the following:

- Water activity (aw) of the spoiled syrup: 0.72–0.75

- pH: 5.5–6.0 (neutral to slightly acidic)

- Contaminants identified:

- Aspergillus spp.

- Penicillium spp.

- Zygosaccharomyces spp. (osmophilic yeast)

It was discovered that:

- Improper sealing allowed moisture ingress and exposure to air

- Ambient humidity in the storage area exceeded 60%

- Containers were not sanitized properly before filling

Root Cause Analysis:

Though the water activity of brown rice syrup is below the threshold for most bacteria, it was within the growth range of xerophilic molds and osmophilic yeasts, which can survive and thrive at aw levels as low as 0.60–0.70.

The high sugar content did not fully inhibit fungal growth because:

- Air exposure allowed oxygen-dependent mold growth

- Slight moisture migration raised localized aw at the surface

- Warm temperatures accelerated microbial metabolism.

Corrective Actions:

- Improved container sealing: Switched to airtight, food-grade packaging with induction seals.

- Controlled storage environment: Kept relative humidity below 50% and reduced storage temperature to <20°C.

- Enhanced sanitation protocols: Cleaned and sanitized all containers and filling equipment prior to use.

- Water activity monitoring: Began routine aw testing of each batch to ensure levels remained below critical thresholds.

Outcome:

- No further spoilage incidents were reported after implementing changes.

- Shelf life was extended by 6+ months.

- Product quality remained consistent, reducing customer complaints and returns.

Key Takeaways:

- Even foods with relatively low water activity — like brown rice syrup — can be vulnerable to fungal and mold spoilage, especially when exposed to oxygen and moisture.

- Monitoring aw, ensuring airtight storage, and maintaining a dry environment are essential for preventing spoilage in sugar-rich products.

Why Measuring Water Activity Matters

Controlling water activity is one of the most effective strategies in food preservation. In pork and other perishable meats, aw monitoring helps:

- Prevent microbial spoilage and foodborne illness

- Extend shelf life

- Ensure product safety during storage and transport

- Support regulatory compliance (e.g., for export)

- HACCP & Food Safety Plans

- Quality consistency

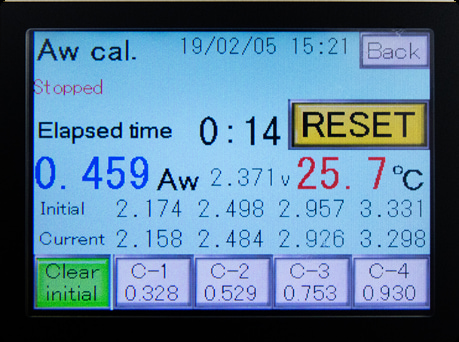

Food manufacturers often use water activity meters to ensure that their products remain within safe aw ranges.

Water Activity as a Food Safety Tool

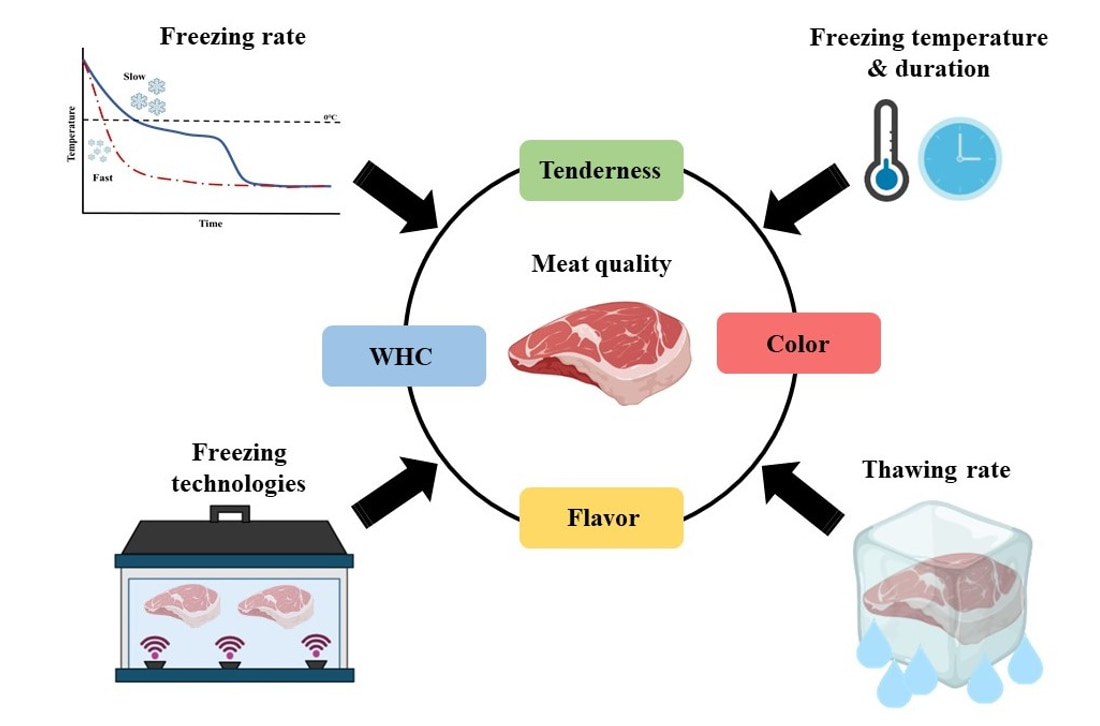

In the meat industry, water activity isn’t used alone — it’s often combined with other preservation methods such as:

- Refrigeration or freezing

- Vacuum or modified-atmosphere packaging

- Use of preservatives (e.g., nitrites, salt)

- pH control (fermentation, acidification)

This combination of techniques, known as the “hurdle concept”, helps create multiple barriers to microbial growth, improving food safety and stability.

Conclusion

Water activity is a vital indicator of food quality and safety, especially for perishable items like pork. High aw in raw pork allows harmful bacteria to thrive, making it essential to control temperature and handling. Meanwhile, reducing water activity through processing methods like drying or curing helps extend shelf life and inhibit microbial growth.

Whether you’re a food processor, quality controller, or just passionate about food safety, understanding and managing water activity is key to producing safer, longer-lasting food.

Water activity is not an abstract scientific concept; it is a practical, powerful, and indispensable parameter in food science. For perishable products like pork, it is the fundamental switch that controls the microbial universe within the product.

By moving from simply measuring moisture content to actively managing water activity, you transition from reacting to spoilage to proactively designing safety, quality, and stability into your pork products from the very beginning.

Frequently Asked Questions (FAQ)

1. What is the difference between water activity and moisture content?

Water activity (aw) measures how much water is available for microbial growth and chemical reactions, while moisture content refers to the total amount of water (both bound and unbound) in a food.

A food can have high moisture content but low water activity if the water is tightly bound (e.g., in sugar or salt-rich foods).

2. Why is water activity important in pork products?

Pork has a high natural water activity, making it highly perishable and a good environment for bacteria. By reducing water activity through methods like drying, curing, or salting, we can extend shelf life and reduce the risk of foodborne illness.

3. What is the typical water activity of raw pork?

Raw pork generally has a water activity between 0.98 and 0.99, which is very high. This makes it an excellent medium for microbial growth and spoilage if not properly stored.

4. How can we reduce water activity in pork?

Water activity in pork can be reduced through:

- Drying or dehydration

- Salting (curing)

- Adding sugar or other humectants

- Fermentation (pH lowering also helps)

- Smoking

These methods make the environment less favorable for bacterial growth.

5. At what water activity do most harmful bacteria stop growing?

Most pathogenic bacteria cannot grow below a water activity of 0.90. Some, like Staphylococcus aureus, can tolerate slightly lower aw (~0.86) but do not produce toxins below that point.

6. Is lowering water activity enough to make pork shelf-stable?

Not by itself. While lowering aw is a major step in preserving pork, other factors such as pH, temperature control, packaging, and use of preservatives are also necessary to ensure safety and extend shelf life.

7. How is water activity measured in meat products?

Water activity is measured using a water activity meter, which determines the vapor pressure of the water in the food compared to pure water. It’s a quick and non-destructive test often used in quality control labs.

8. Can frozen pork have microbial growth despite low temperature?

Freezing stops microbial growth by making water unavailable, but it does not kill all bacteria. Once thawed, the water becomes available again (high aw), and bacteria can quickly resume growth — which is why proper thawing and handling are critical.

9. How does packaging affect water activity?

Packaging doesn’t directly change water activity, but it helps maintain the current aw by preventing moisture gain or loss. Vacuum or moisture-barrier packaging also helps prevent microbial contamination and spoilage.

10. What happens if water activity is too high in stored pork?

If water activity remains high (above 0.95) in stored pork — especially without proper refrigeration — it creates ideal conditions for bacterial spoilage and the growth of pathogens. This can lead to:

- Off-odors

- Slimy texture

- Discoloration

- Risk of foodborne illnesses

11. Can spoilage organisms grow at lower water activity levels?

Yes. While many harmful bacteria require higher aw levels, yeasts and molds can grow at lower aw (as low as 0.60–0.70), particularly in cured or dried pork. That’s why products like dry-cured sausages sometimes show mold growth if not properly stored or protected.

12. What water activity level is considered safe for shelf-stable meat products?

To be shelf-stable without refrigeration, meat products typically need to have:

- aw < 0.85, which inhibits most pathogens

- Sometimes combined with pH < 4.6, to further prevent microbial growth

This is why dry-cured meats (e.g., salami, jerky) can be stored at room temperature if processed and packaged correctly.

13. Does lowering water activity affect taste or texture?

Yes. Reducing aw often changes the texture, making products drier or firmer (like jerky or dry-cured ham). It may also concentrate flavors, which is desirable in many cured meat products. However, excessive drying can make products tough or unpalatable if not controlled carefully.

14. Is water activity regulated by food safety authorities?

Yes. Regulatory agencies such as the USDA, FDA, EFSA, and others often reference water activity in food safety standards, particularly for ready-to-eat and shelf-stable products. For example:

Foods with aw < 0.85 are often exempt from some microbial testing requirements because pathogens can’t grow.

15. How often should water activity be tested in food production?

For food manufacturers, especially those producing meat and poultry products, it’s recommended to:

- Test each batch during product development or process changes

- Perform routine checks during production for quality control

- Validate aw levels after formulation adjustments (e.g., salt, sugar, drying time)

16. Can water activity affect food labeling or classification?

Yes. In some jurisdictions, the classification of a product as “shelf-stable” or “refrigerated” depends on water activity and pH levels. This can influence:

- Labeling requirements

- Storage instructions

- Distribution logistics

Accurate aw measurement ensures compliance and prevents recalls.

17. How does water activity relate to HACCP in meat processing?

Water activity is a critical control point (CCP) in many HACCP (Hazard Analysis and Critical Control Points) plans, especially for:

- Cured meats

- Dried or fermented sausages

- RTE (Ready-to-Eat) products

Monitoring and controlling aw helps prevent microbial hazards and ensures food safety compliance.

18. Can salt alone reduce water activity in pork?

Salt is a common way to reduce water activity because it binds free water, making it unavailable to microbes. However, salt alone may not be sufficient to reach aw levels below 0.85. Combining salting with drying or fermentation is often necessary for full microbial control.

Need help measuring or controlling water activity in your pork or food products?

Our team offers professional support and testing solutions for meat processors and food manufacturers. Contact us today to learn more!

Contact :

- Mobile/WhatsApp: +971526191767

- Email: sales@apex-instrument.com