In the metallurgy industry, precision and reliability aren’t just nice to have, they’re essential. The composition of metals directly affects their performance, durability, and compliance with stringent industry standards. Whether it’s aerospace-grade alloys or structural steel for bridges, accurate elemental analysis is non-negotiable. This is where Optical Emission Spectrometers (OES) come into play.

In steel mills where molten metal flows like rivers of fire, in aerospace labs where titanium alloys decide human safety, and at scrap yards sorting metallic waste, a silent technological sentinel stands guard: the Optical Emission Spectrometer (OES). This unassuming instrument has become the cornerstone of metallurgical quality control, with over 85% of primary metal producers and leading metal testing labs relying on spark OES for elemental analysis. As industries demand increasingly precise material properties, OES bridges the gap between raw metal and engineered perfection.

What is an Optical Emission Spectrometer?

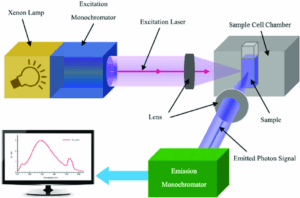

An Optical Emission Spectrometer is an analytical instrument used to determine the elemental composition of metals.

OES technology is known for its speed, accuracy, and ability to detect a wide range of elements, including carbon, sulfur, phosphorus, and other trace elements critical in metallurgical analysis.

Why is OES Crucial for Metallurgy Industries?

- Quality Control and Assurance

OES allows real-time verification of metal grades and compositions during production. This process ensures that every batch meets the required specifications and helps reduce the risk of costly rework or product rejection.

- Trace Element Detection

Metallurgy is not just about iron and carbon. Minor elements like nitrogen, boron, and vanadium can have a significant impact on a metal’s characteristics. OES systems are highly sensitive, enabling laboratories to detect these trace elements down to parts-per-million (ppm) levels.

- Speed and Efficiency

Time is money in industrial settings. OES can deliver results in seconds, enabling on-the-spot decision-making during smelting, casting, or forging operations. This rapid feedback loop minimizes production downtime and waste.

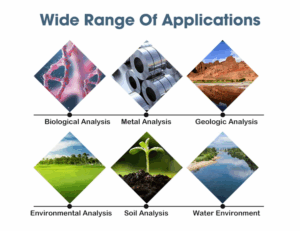

- Versatility Across Alloys

Whether you’re dealing with ferrous metals (like steel and cast iron) or non-ferrous metals (such as aluminum, copper, or nickel-based alloys), OES can analyze them all. This makes it a go-to solution for multi-material testing labs and alloy development projects.

- Regulatory Compliance and Certification

Global standards like ASTM, ISO, and DIN require strict adherence to material composition. OES plays a vital role in ensuring that metals meet these standards, making certification and compliance straightforward.

OES in Metal Testing Laboratories

- High throughput: Labs can process dozens or hundreds of samples per day.

- Low operating costs: Minimal sample preparation and consumables.

- Reproducibility: Reliable, repeatable results that withstand third-party validation.

Many modern OES systems are also equipped with automated sample changers, cloud-based data storage, and LIMS (Laboratory Information Management System) integration, enabling seamless workflows in high-demand environments.

Where Metal Meets Machine: Critical Applications

► Positive Material Identification (PMI)

Misidentifying 316L stainless steel in a chemical reactor can lead to $2 million in chloride corrosion damage. OES-based positive material identification (PMI) verifies alloy grades in seconds during goods receipt. Bossard reports a 99.7% reduction in material mix-ups using this method.

► Scrap Recycling Revolution

OES-enabled handheld analyzers:

- Sort 40 tons/hour of shredded auto scrap

- Recover $520/ton nickel superalloys from waste streams

- Cut copper smelting energy by 60% versus virgin ore

► Aerospace & Automotive Certification

Titanium turbine blades require checks for more than 50 elements. OES provides full ASTM E1251 compliance with NIST-traceable certificates. IMR Labs processes over 5,000 aerospace samples every month using this technology.

Why Metallurgy Can’t Live Without OES: 5 Transformative Advantages

- Comprehensive Elemental Coverage

This is critical for steel hardening, where 0.01% carbon variation means life-or-death failure in gear components.

- Real-Time Process Control

In electric arc furnaces, OES monitors melt chemistry every 90 seconds. If manganese levels fall below specification, it triggers automatic alloy additions before tapping, saving $500,000 per hour in potential rework. One aluminum smelter reduced off-spec batches by 73 percent by using OES-driven process adjustments.

- Defect Prevention Through Inclusion Analysis

Non-metallic inclusions such as Al₂O₃ and SiO₂ can weaken metals catastrophically. OES detects these “silent killers” at levels of 10 ppm or less, which is impossible with traditional wet chemistry. By implementing OES inclusion screening, a bearing manufacturer eliminated 98 percent of fatigue failures.

- Unmatched Efficiency

- Speed: 40 elements/minute vs. 4 hours via ICP-MS

- Throughput: 400 samples/day with automated spark OES

- Cost: $12/sample (OES) vs. $180 (combustion analysis) for carbon testing

Table: OES vs. Competing Techniques in Metallurgy

| Technique | Detection Limits | Key Limitations | Cost per Sample |

| Spark OES | 1 ppm – 100% | Surface prep required | $10–$50 |

| XRF | 10 ppm – 100% | Poor for light elements | $15–$70 |

| ICP-MS | 0.1 ppb – ppm | Liquid samples only | $150–$400 |

| Combustion Analysis | Carbon/S-only | Single-element | $80–$200 |

- The Ultimate Production Safety Net

When a German steel plant’s primary OES failed during a 2,000-ton heat treatment run, their benchtop Spark OES Spectrometer.

- Processed 142 samples in 8 hours

- Maintained ±0.03% accuracy vs. primary instrument

Prevented $1.2M in scrap losses

Conclusion: Beyond the Spark

In an industry where even the smallest impurity can cause major failures, Optical Emission Spectrometry is indispensable. From ensuring product integrity to supporting innovation in alloy development, OES enables metallurgy industries and testing laboratories to operate with confidence and precision.

If your operation works with metals, it’s time to invest in the analytical power of OES. The benefits in accuracy, efficiency, and compliance make it a worthwhile investment.

Optical Emission Spectrometry has evolved beyond being just an analytical tool. It now serves as the central nervous system of intelligent metallurgy. As one of the most advanced material testing instruments, OES ensures that jet engines can endure Mach 5 stresses and that surgical implants remain safe, providing the elemental truth that guarantees material integrity.

If you are looking for OES Spectrometer/Analyzer for your metal lab/metallurgy industry with the latest detection technology;

Contact us today at www.apexinstrument.me

For expert guidance and solutions tailored to your needs.

- Mobile/WhatsApp: +971526191767

- Email:sales@apex-instrument.com