Leading Material Testing Equipment Supplier in Dubai & UAE

One-Stop Solution for Soil, Concrete & Material Testing Equipment Across GCC & MENA

Unlock Precision with Industry-Leading Material Testing Solutions

Ensure Strength, Safety, and Quality Across Every Industry:

Material testing equipment is essential for analyzing the mechanical, physical, and chemical properties of Metals, Polymers, Soils, Concrete, Composites, and more. From quality assurance to R&D, discover how our advanced testing solutions support critical applications across construction, automotive, aerospace, building materials, manufacturing, and academic research.

As a trusted material testing equipment supplier in UAE, we provide high-performance tools that support both quality assurance and research & development needs.

Uses of Material Testing Equipment

- Tensile, compression, and fatigue testing

- Hardness and impact resistance assessment

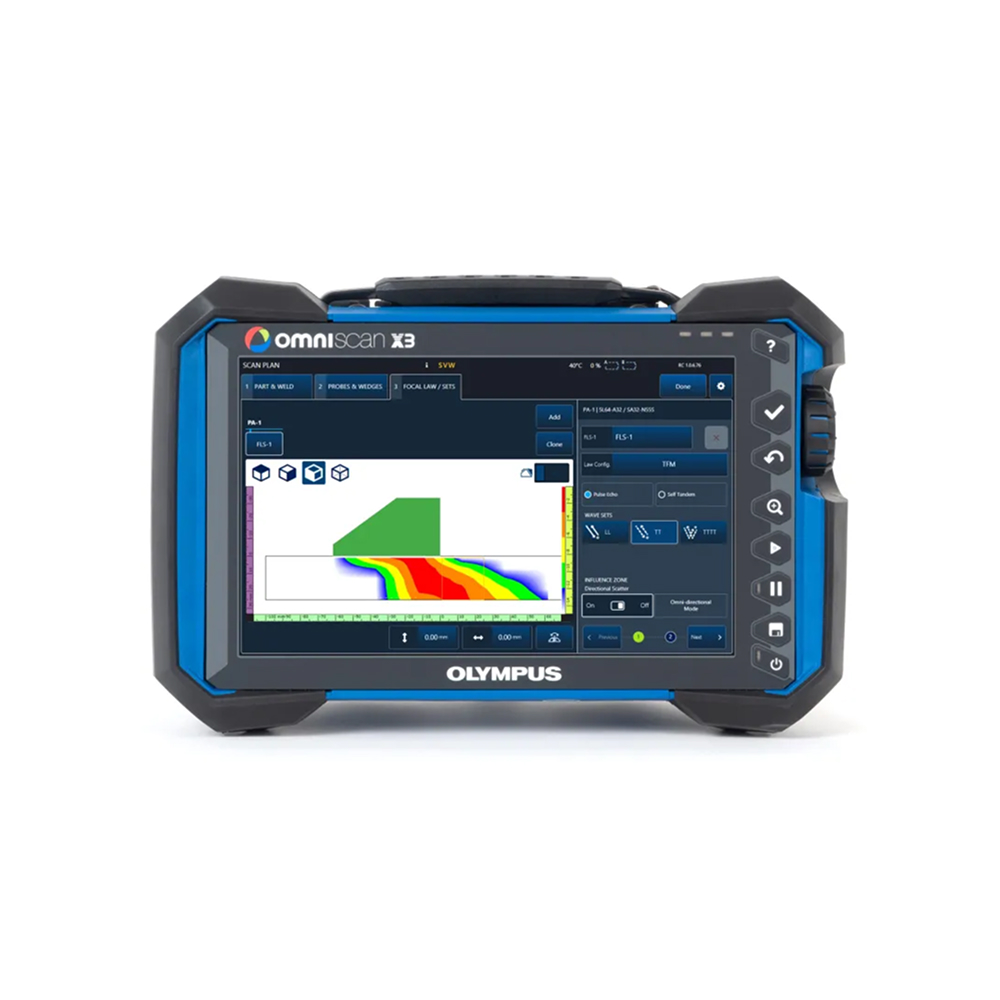

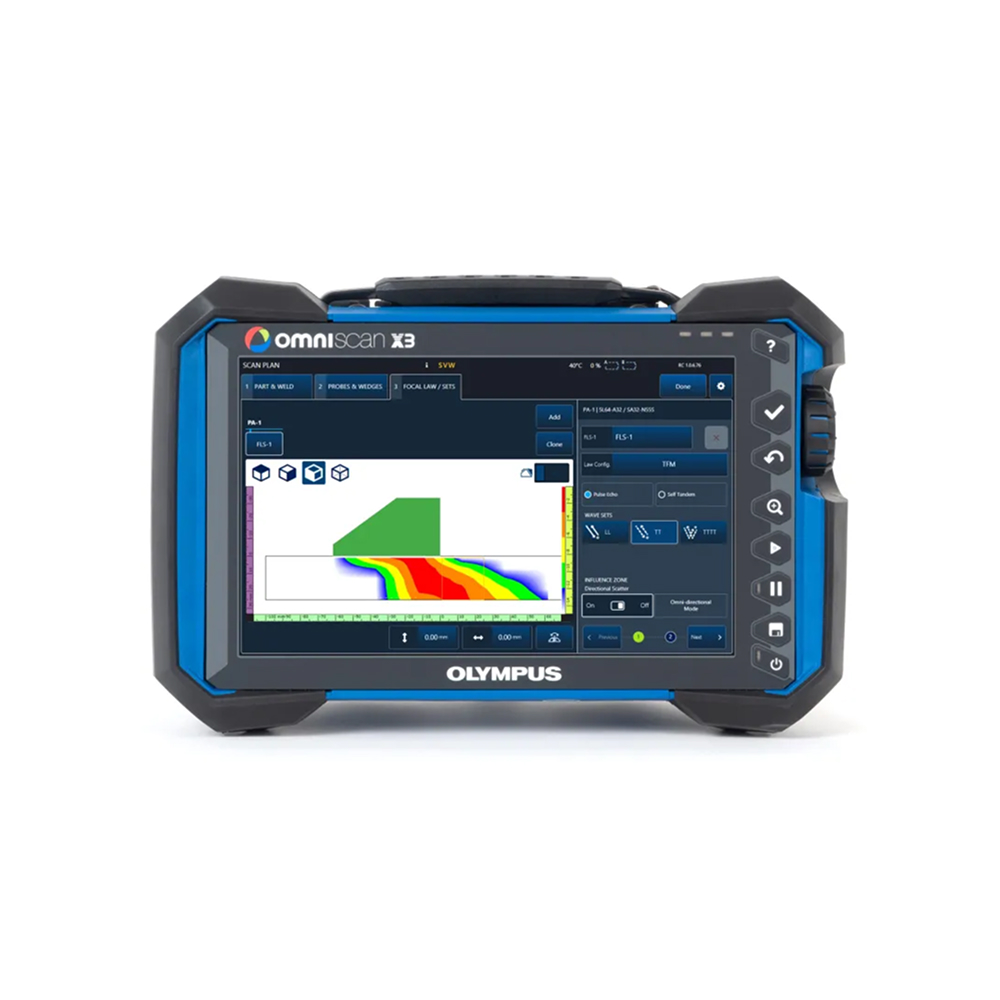

- Non-destructive testing (NDT) for internal flaws

- Environmental and thermal testing

Industries We Serve with Material Testing Equipment

Construction

Verify concrete and steel integrity

Automotive

Test components for durability and performance

Aerospace

Ensure materials meet safety and compliance standards

Academia & Research

Support innovation and material development

Your material’s limits define your product’s legacy. Push them with precision

John Doe

Industry-Specific Applications: Turning Testing Challenges into Practical Solutions

Table: Role of Material Testing Equipment Across Key Industries.

| Industry | Critical Tests | Equipment Used | Impact |

|---|---|---|---|

| Aerospace | Fatigue resistance, crack propagation | Servo-hydraulic testers, NDT | Prevents in-flight failures; certifies composites for hypersonic flight |

| Automotive | Crash simulation, component durability | Impact testers, universal testers (UTMs) | Ensures airbags deploy correctly; validates EV battery structural safety |

| Construction | Concrete compressive strength, rebar tensile integrity | Compression testers, UTMs | Guarantees skyscraper resilience against earthquakes/loads |

| Medical Devices | Biocompatibility, implant fatigue life | Dynamic testers, environmental chambers | Verifies hip implants last 20+ years; tests surgical tool sterilization stability |

| Packaging | Tear resistance, shelf-life validation | Peel testers, humidity chambers | Prevents food spoilage; ensures e-commerce parcels survive transit |

| Industry | Critical Tests | Equipment Used | Impact |

|---|---|---|---|

| Aerospace | Fatigue resistance, crack propagation | Servo-hydraulic testers, NDT | Prevents in-flight failures; certifies composites for hypersonic flight |

| Automotive | Crash simulation, component durability | Impact testers, universal testers (UTMs) | Ensures airbags deploy correctly; validates EV battery structural safety |

| Construction | Concrete compressive strength, rebar tensile integrity | Compression testers, UTMs | Guarantees skyscraper resilience against earthquakes/loads |

| Medical Devices | Biocompatibility, implant fatigue life | Dynamic testers, environmental chambers | Verifies hip implants last 20+ years; tests surgical tool sterilization stability |

| Packaging | Tear resistance, shelf-life validation | Peel testers, humidity chambers | Prevents food spoilage; ensures e-commerce parcels survive transit |

In materials, we trust—but we verify. Testing is the bridge between theory and survival.

John Doe