Introduction

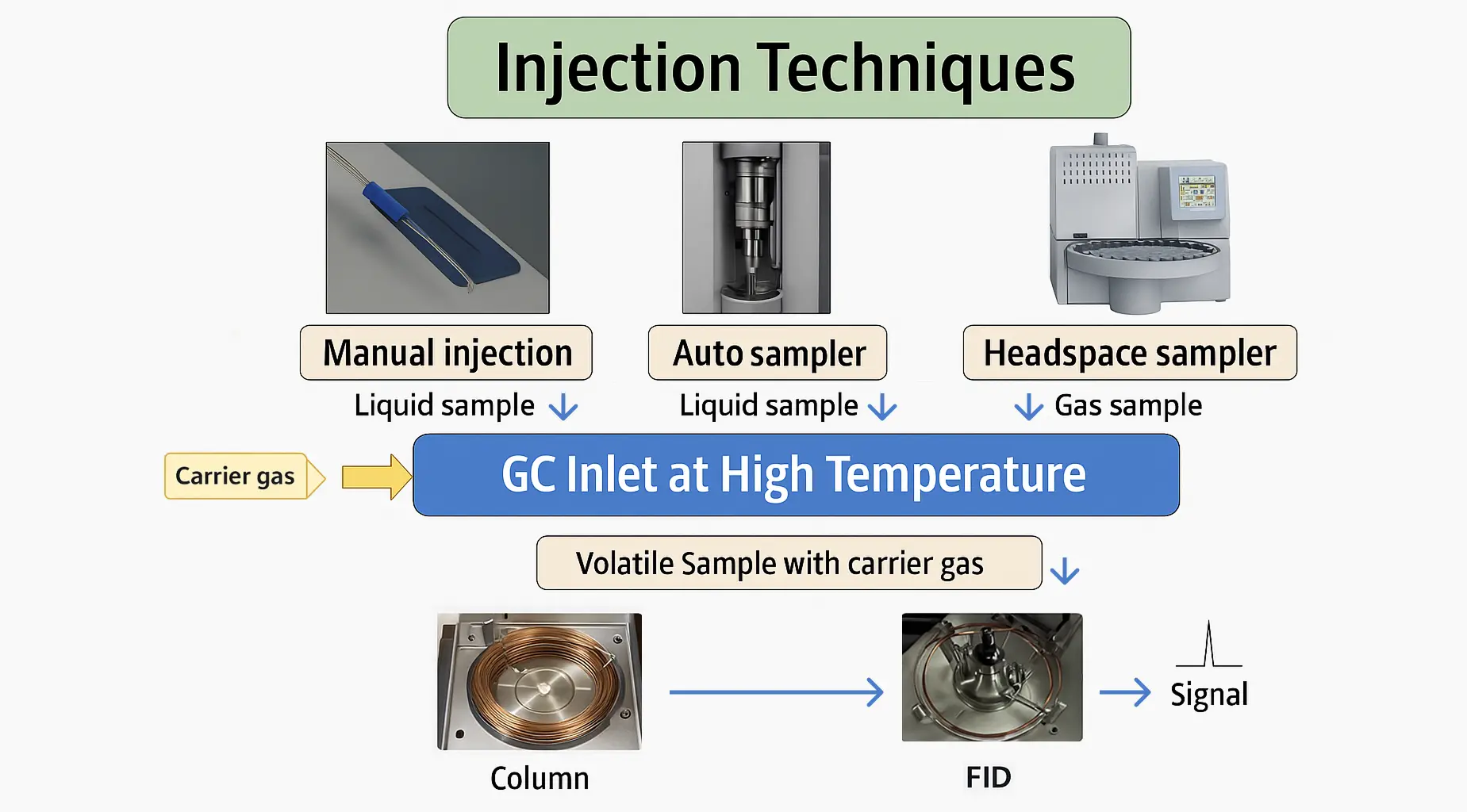

GC Headspace is an advanced sampling technique that detects volatile solvents and compounds present in the gas phase above a solid or liquid sample. This method provides accurate measurement of volatile substances that naturally evaporate from materials under controlled conditions.

Analysis of residual solvents Or Volatile Organic compounds (VOC) in printing and packaging materials can be easily performed by GC Headspace Autosampler system with FID detector with high precision and accuracy.

In the printing and packaging industries, product safety, quality control, and regulatory compliance are non-negotiable. Gas Chromatography (GC) equipped with headspace autosamplers has become an indispensable tool for detecting volatile organic compounds (VOCs), residual solvents, and contaminants that impact material performance and compliance.

Key Applications of GC Headspace Autosamplers

- Residual Solvent Analysis in Inks & Coatings

Printing inks and coatings often contain solvents like toluene, ethyl acetate, or methanol. A GC headspace autosampler automates the detection of these VOCs, ensuring they fall within safe limits (e.g., EPA, REACH, and FDA standards).

- Migration Testing for Food-Safe Packaging

When packaging interacts with food or pharmaceuticals, harmful compounds can migrate. Headspace GC identifies trace volatiles (e.g., plasticizers, adhesives) to comply with EU 10/2011, FDA 21 CFR, and USP <467> regulations.

- Odor Profiling in Recycled Materials

Unwanted odors in recycled paper or plastic packaging? GC headspace analysis pinpoints the source—whether it’s residual solvents, degradation byproducts, or contaminants from manufacturing.

- Sterilization Validation for Medical Packaging

Medical packaging sterilized with ethylene oxide (EtO) must pass strict residual limits. Automated headspace sampling ensures ISO 10993-7 and FDA compliance by accurately measuring EtO traces.

- Adhesive & Laminate Quality Control

Poorly cured adhesives can release solvents, compromising seal integrity. GC headspace testing monitors solvent retention, optimizing curing processes and preventing packaging failures.

6. Reduced Environmental Impact

By providing a means to accurately measure and control VOC emissions, GC headspace autosamplers also help reduce the environmental impact of the printing and packaging industry. Excessive VOCs can contribute to air pollution and pose risks to human health, so minimizing these emissions is essential for companies that are committed to sustainability.

Using GC technology, manufacturers can ensure that their processes are environmentally friendly and that their products comply with environmental regulations, contributing to a healthier planet.

Why Choose GC Headspace Automation?

✔ Precision – Detects ppm/ppb-level volatiles reliably detect with high precision and accuracy.

✔ Efficiency – High-throughput autosamplers streamline testing for fast production cycles.

✔ Compliance – Meets global standards for safety and sustainability.

Conclusion

From preventing ink odors to validating sterile medical packaging, GC headspace autosamplers provide the accuracy and speed needed to maintain quality and compliance in the printing and packaging sectors.

By offering enhanced sensitivity, regulatory compliance, and improved quality control, GC headspace autosamplers empower manufacturers to meet the growing demands for safer, higher-quality products. Whether you are testing for residual solvents, VOCs, or other volatile compounds, this technology plays a crucial role in ensuring that your products are both safe and of the highest quality.

For businesses in the printing and packaging industries, investing in GC headspace autosamplers is not just a smart decision; it’s a necessary step toward maintaining high standards of quality and regulatory compliance while meeting the expectations of an ever-demanding market.