In the growing market of health supplements and fortified foods, the accurate detection and quantification of multivitamins is essential. Consumers depend on product labels to reflect what’s actually inside their supplements—and so do regulators. This is where High-Performance Liquid Chromatography (HPLC) becomes a powerful tool.

HPLC offers a highly sensitive, precise, and reproducible method for detecting a broad range of vitamins, whether water- or fat-soluble, across tablets, capsules, liquids, and even fortified foods. In this post, we’ll explore how HPLC works for multivitamin analysis, the typical workflow, and why it’s the industry standard for nutritional testing.

Why Analyze Multivitamins?

Multivitamins contain a complex mix of nutrients such as:

- Water-soluble vitamins: B-complex group (B1, B2, B3, B6, B12), Vitamin C, Folic Acid, etc.

- Fat-soluble vitamins: Vitamins A, D, E, and K

Due to the chemical diversity among these compounds, analyzing all of them in one go is challenging. That’s why tailored HPLC methods are employed to detect each group accurately.

What is HPLC?

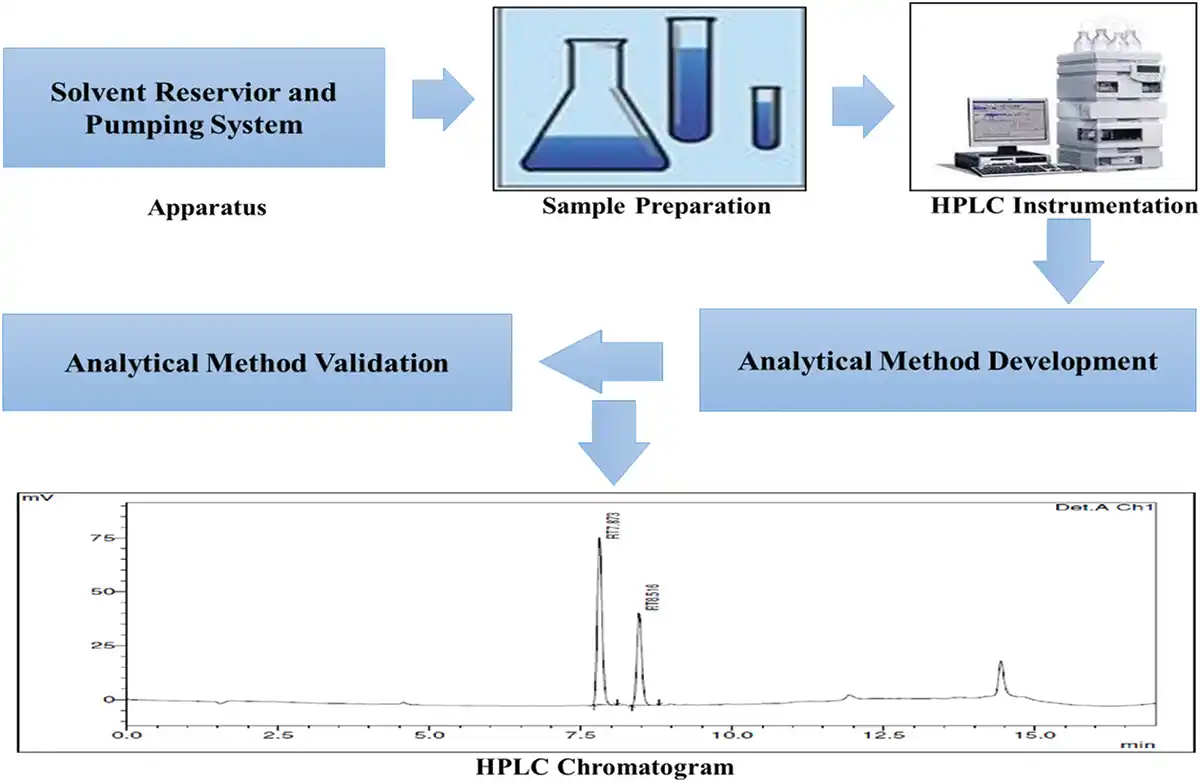

HPLC is an analytical liquid Chromatography instrument. It’s especially useful when analyzing complex samples—like multivitamins—that contain multiple substances in varying concentrations.

Key Components of an HPLC System:

- Pump: Pushes solvent through the system.

- Injector: Introduces the sample.

- Column: It is used for the separation of molecules in a mixture.

- Detector: It detects each component present in mixture.

- Data System: Records and interprets results.

Sample Preparation: The Foundation of Good Data

Before vitamins can be analyzed, the sample must be prepared properly. This involves:

- Grinding the tablet or capsule for homogenization.

- Extraction using a solvent system (e.g., methanol, water, or phosphate buffers) tailored to the vitamin type.

- Filtration through 0.22 or 0.45 µm filters to remove particulate matter.

- Stabilization with light protection or antioxidants (especially for sensitive vitamins like B12 or folic acid).

HPLC Conditions for Vitamin Detection

Different vitamins require different separation conditions. Here’s a general outline:

- Water-Soluble Vitamins (B-complex, Vitamin C)

- Column: C18 reverse-phase

- Mobile Phase: Gradient of water with phosphate buffer and methanol or acetonitrile

- Detection: UV-Vis detector (190–280 nm range)

- Typical Retention Times:

- Vitamin B1 (Thiamine): ~4–6 min

- Vitamin B2 (Riboflavin): ~7–9 min

- Vitamin B6 (Pyridoxine): ~10–12 min

- Vitamin C (Ascorbic acid): ~3–5 min

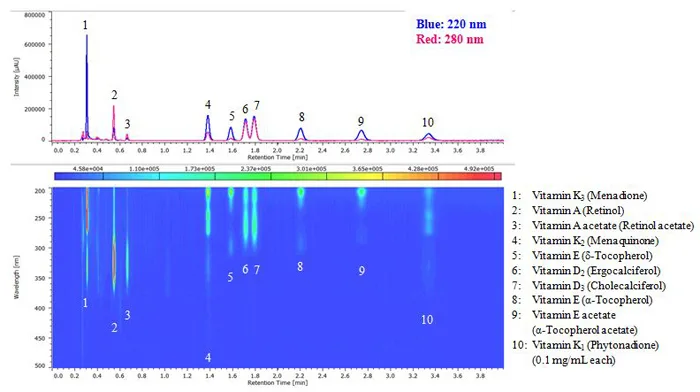

- Fat-Soluble Vitamins (A, D, E, K)

- Column: C18 or silica-based

- Mobile Phase: Nonpolar solvents like hexane, methanol, or isopropanol

- Detection: UV-Vis or fluorescence (depending on the vitamin)

- Typical Retention Times:

- Vitamin A: ~10–15 min

- Vitamin E: ~20–25 min

- Vitamin D: ~15–18 min

- Vitamin K: ~12–16 min

Detection and Quantification

HPLC systems often use Photodiode Array (PDA) or UV-Vis detectors to monitor multiple wavelengths at once. The system generates chromatograms with peaks that correspond to each vitamin. These peaks are:

- Identified based on retention time

- Quantified using calibration curves made from known vitamin standards

This allows for precise measurement of each vitamin’s concentration in the sample.

Challenges in Multivitamin Detection

While HPLC is powerful, it’s not without challenges:

- Vitamin degradation: Sensitive compounds like folic acid or vitamin C can degrade if not handled properly.

- Matrix interference: Fillers and excipients in tablets can interfere with detection.

- Separation complexity: Some vitamins have similar chemical properties and require careful method development to separate.

These issues are mitigated through method optimization and strict quality control protocols.

Applications Across Industries

HPLC-based multivitamin analysis is widely used in:

- Pharmaceutical quality control

- Nutritional supplement manufacturing

- Fortified food analysis (e.g., cereals, beverages)

- Regulatory compliance testing (FDA, EFSA, etc.)

- Research in bioavailability and nutrient stability

The Future: Next-Generation Vitamin Analysis

- Portability:

Compact HPLC-PDA systems enable field testing during supply chain transit, catching degradation in temperature-exposed shipments.

- AI Integration:

Machine learning predicts retention shifts during method transfer, reducing revalidation time by 70%

- Hyphenated Systems:

LC-MS/MS is a very powerful instrument that detects compounds in a mixture at the molecular level based on their mass-to-charge ratios.

Conclusion:

HPLC is an excellent analytical instrument which is widely used in Pharm, Foods, Forensic and research and Development Laboratories. Its ability to handle complex mixtures, detect low concentrations, and ensure product consistency makes it a gold standard in analytical nutrition science.

HPLC-based multivitamin analysis transcends technical achievement—it embodies a commitment to transparency in the $151 billion supplement industry. As regulatory scrutiny intensifies globally, methods balancing speed (22-minute runs), sustainability (green solvent systems), and accuracy (RSD <2%) will define next-generation quality control. For consumers, this science ensures that each capsule delivers precisely what its label promises—nothing less.

At Apex Instrument, we recognize the critical role HPLC plays in modern supplement testing. Whether you’re a food scientist, quality assurance technician, or supplement formulator, mastering HPLC for multivitamin detection offers powerful insights and product confidence.