Collapsible aluminum tubes are widely used in packaging applications across industries such as pharmaceuticals, cosmetics, food, and adhesives due to their protective barrier properties, malleability, and ability to maintain product integrity. One of the most critical components in the construction of these tubes is the internal lacquer — a protective coating applied to the inner surface to prevent direct contact between the aluminum and the contents of the tube.

Ensuring the quality and integrity of the internal lacquer is vital. A failure in the lacquer coating can lead to corrosion of the aluminum, contamination of the product, and a potential health hazard for end users. Therefore, it is essential to implement rigorous quality control measures, including testing methods such as the internal coating continuity test.

In this blog post, we’ll explore:

- What internal lacquer is and why it matters

- Common defects in internal coatings

- The role of the Internal Coating Continuity Tester

- How the test works

- Factors affecting testing outcomes

- Best practices for ensuring accurate results

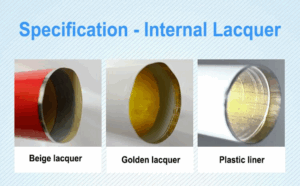

What Is Internal Lacquer and Why Is It Important?

Internal lacquer (or internal coating) is a thin layer of epoxy or polyester resin applied inside aluminum tubes. Its main purpose is to:

- Protect the tube contents from coming into contact with bare aluminum, which could trigger unwanted chemical reactions.

- Prevent aluminum corrosion, which can compromise the structural integrity of the tube and its barrier properties.

- Ensure product purity and shelf life, particularly in pharmaceutical and cosmetic applications.

The quality of this coating must be consistent and defect-free. Even microscopic pinholes or cracks in the lacquer layer can be problematic, as they allow the contents to interact with the aluminum surface.

Common Defects in Internal Lacquer Coating

Despite advancements in manufacturing techniques, several types of defects can still occur during the lacquering process:

- Pinholes – Tiny holes caused by uneven application or contamination during coating

- Cracks – Can occur due to thermal or mechanical stress during the curing process

- Incomplete coverage – Often caused by poor spray gun calibration or coating viscosity issues

- Contamination – Dust, oil, or other particles that interfere with proper adhesion

- Overbaking or underbaking – Affects the flexibility and adherence of the lacquer

Identifying these defects early in the manufacturing process is crucial. That’s where the Internal Coating Continuity Tester comes into play.

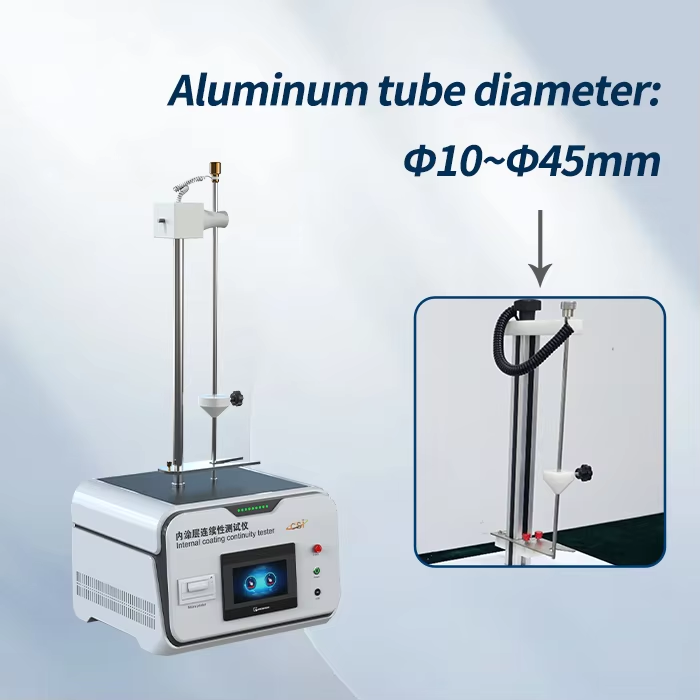

What Is an Internal Coating Continuity Tester?

An Internal Coating Continuity Tester is a specialized piece of equipment used to assess the integrity of the internal lacquer in collapsible aluminum tubes. This tester detects discontinuities — such as pinholes or areas with insufficient coating — by measuring electrical conductivity between the tube’s interior and exterior.

Since aluminum is conductive and the lacquer is not, the tester can detect areas where the lacquer fails to insulate the inner wall of the tube.

How the Internal Coating Continuity Test Works

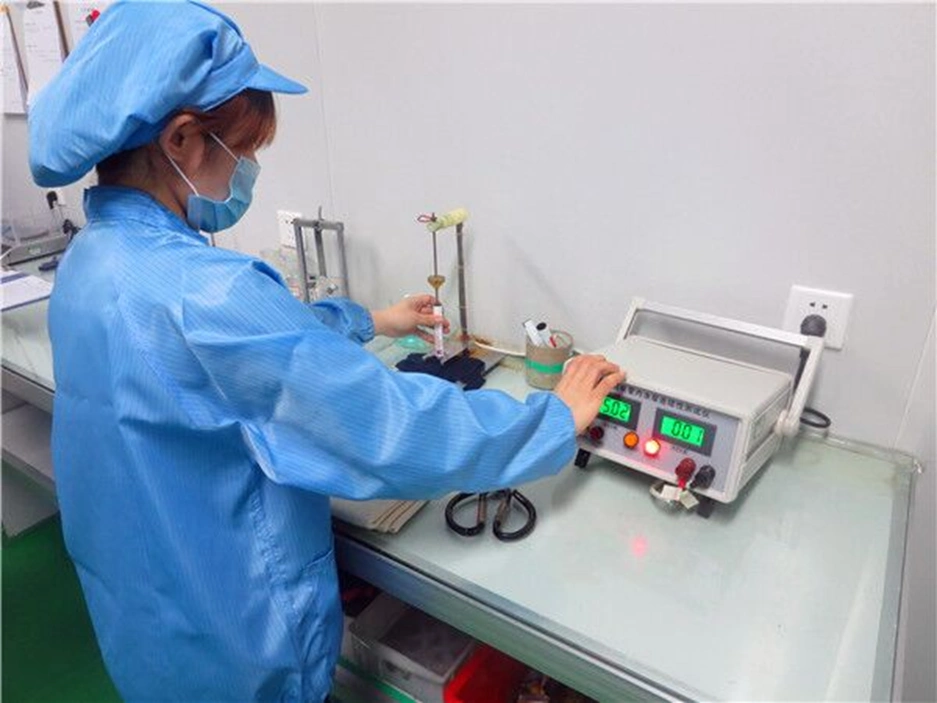

Here’s a step-by-step breakdown of how the testing process typically works:

- Test Setup

- The aluminum tube is mounted onto a test fixture.

- A conductive electrolyte solution (usually a saline solution) is poured into the tube to make contact with any exposed aluminum inside.

- A probe (electrode) is inserted into the electrolyte, and the tube is grounded or connected as the second electrode.

- Electrical Circuit Creation

- A low-voltage current is passed between the internal electrode (in the electrolyte) and the tube body (external electrode).

- The lacquer acts as an insulator. If there are any pinholes or defects, the current will pass through those areas.

- Detection and Indication

- When the tester detects current flow (i.e., a breach in insulation), it registers a “fail” signal.

- The output is usually displayed on a screen or indicator, and many systems log the result or trigger alarms.

- Analysis

- Some testers offer detailed data logging for traceability.

- Test results are evaluated against preset thresholds to determine whether the tube passes or fails.

Equipment Features to Consider

When selecting an internal coating continuity tester, look for:

- High sensitivity – Ability to detect micro-defects as small as 1 micron

- Digital readout – For precise pass/fail evaluation

- Adjustable voltage settings – To tailor the test for different tube sizes or coating thicknesses

- Automated testing capability – For high-volume production environments

- Data logging and traceability – Useful for quality audits and regulatory compliance

Factors Affecting Test Accuracy

Several factors can influence the accuracy of the internal lacquer continuity test:

- Tube Cleanliness

Residual oil or contaminants inside the tube can affect conductivity and give false readings.

- Electrolyte Solution

Concentration and type of electrolyte can affect the sensitivity of the test.

- Lacquer Thickness

Very thin lacquer layers may still insulate well, but increased sensitivity is needed to detect minor inconsistencies.

- Equipment Calibration

Regular calibration is crucial to maintain accuracy and repeatability.

- Environmental Conditions

Temperature and humidity can impact the lacquer’s dielectric properties and test sensitivity.

Best Practices for Ensuring Accurate Testing

To ensure the most reliable results when testing internal lacquer quality:

- Standardize your procedure – Use a consistent test protocol for every batch.

- Train personnel – Ensure operators understand both the equipment and the significance of the results.

- Regular maintenance – Keep test equipment clean and well-calibrated.

- Implement controls – Use control tubes with known defects to verify equipment performance.

- Use statistical process control (SPC) – Track results over time to identify trends or shifts in coating quality.

Conclusion

Ensuring the quality of the internal lacquer in collapsible aluminum tubes is not just a technical requirement—it’s a critical factor in safeguarding product performance and consumer safety. An Internal Coating Continuity Tester offers a reliable, efficient, and accurate method for identifying defects in internal coatings.

By understanding how the test works, what factors affect its reliability, and how to implement it properly within a quality control system, manufacturers can uphold the highest standards of product integrity and compliance.

Whether you’re a tube manufacturer or a quality assurance professional in the pharmaceutical or cosmetic industries, investing in accurate internal lacquer testing is a proactive step toward minimizing risk and maximizing customer satisfaction.

Need Help Choosing the Right Internal Coating Continuity Tester?

Contact us for expert advice, technical specifications, or a quote tailored to your production needs.

Contact :

- Mobile/WhatsApp: +971526191767

- Email: sales@apex-instrument.com